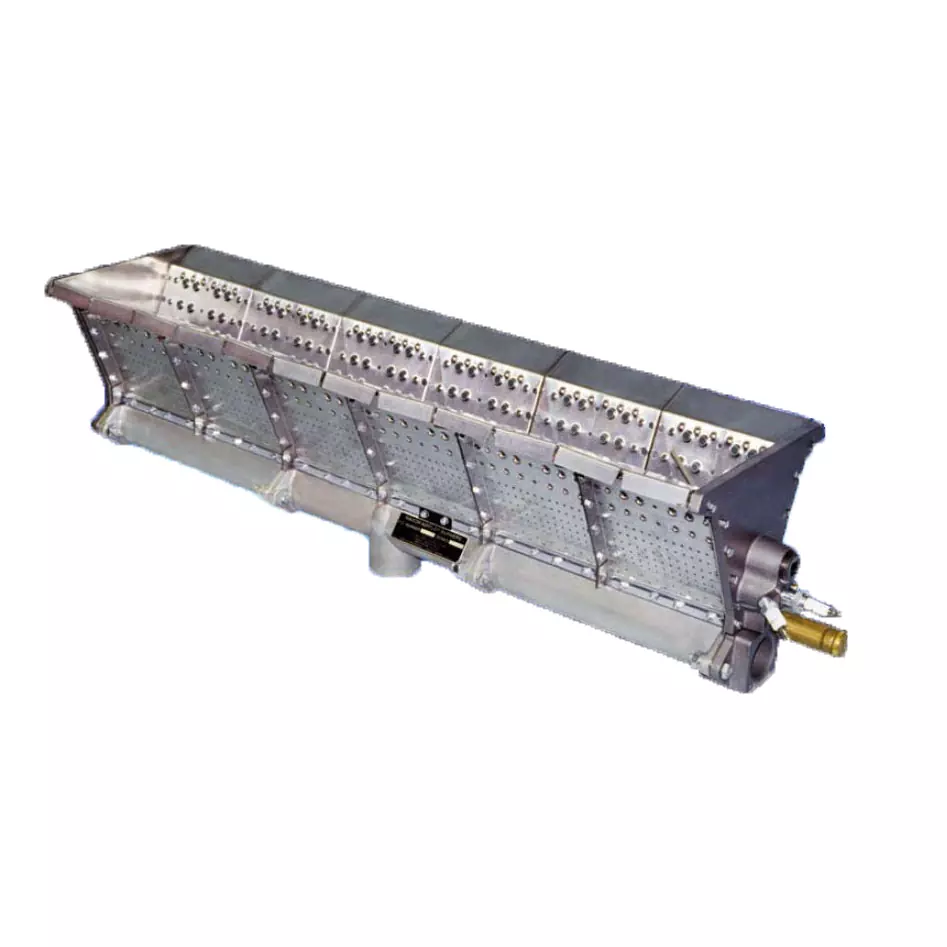

MAXON NP-LE EMISSIONS AIRFLO® Natural Gas Burner

Maxon NP-LE burner is designed for direct-fired make-up air and process applications. This industrial burner improves emissions performance over other gas burners with significantly lower levels of CO and NO2. Higher capacities of up to 1,000,000 Btu/hr/ft (300 kW/ft) make NP-LE a more economical solution for your application. The NP-LE Series easily meets ANSI/CSA/CE direct fired industrial heating standards. In addition, it is available in low pressure versions and in corrosion-proof materials.

For Make-up Air Heating

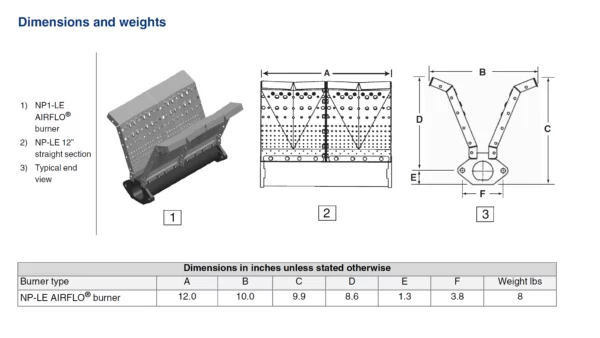

For fresh, ambient air heating, the NP1-LE and NP2-LE AIRFLO burner types provide a nominal capacity of 1.0 MBtu/h per foot with a turndown of 30:1. NP2-LE AIRFLO burners are selected when gas supply pressures are too low for NP1-LE burners.

For Process Air Heating

NP1-LE and NP2-LE AIRFLO burners may be used if temperature rise does not exceed 760°F . Upstream process air temperatures should not exceed 600°F. Downstream temperatures should be limited to 1000°F. NP1-LE and NP2-LE AIRFLO® burners can be supplied with special aluminum alloy bodies for corrosive applications. The use of aluminum alloy bodies limits the maximum allowed upstream process air temperature to 445°F. Downstream temperature should not exceed 840°F.

Materials of Construction

NP1-LE AIRFLO® burners are available in three material choices:

- Standard – cast iron body and end plates

- AL – aluminum body with cast iron end plates

- ALSS – aluminum body and back-up bars, nickle plated end plates, stainless steel fasteners

NP2-LE AIRFLO® burners are available in two material choices:

- Standard – cast iron body and end plates

- AL – aluminum body with cast iron end plates